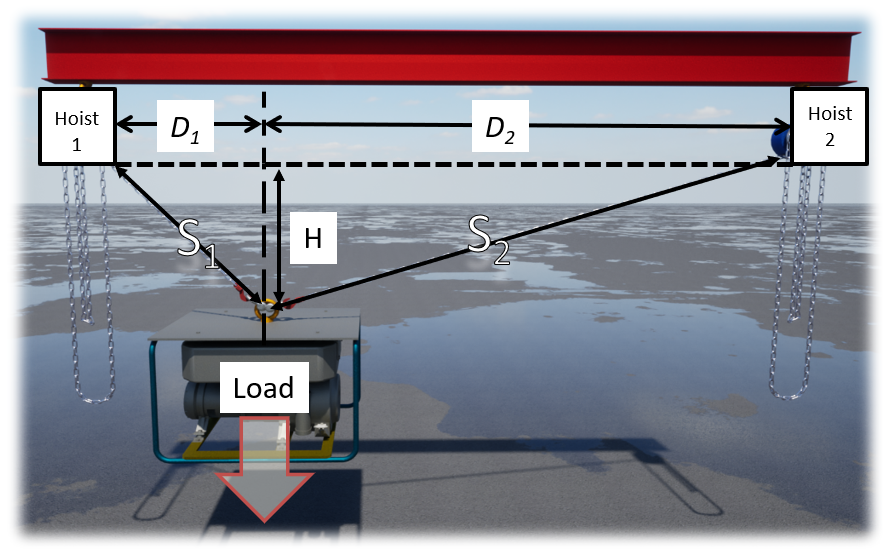

It’s important to note that the tension on a sling can vary greatly depending on the sling angle, the weight of the load, and other factors. Riggers should carefully consider these factors and make necessary calculations to ensure that the sling and rigging equipment are capable of safely handling the load. on the example below, we have 2 slings attached to 2 hoists and 1 lift point. Under these conditions, we can calculate the tension on each sling by using the equations presented below. Please review these equations and when you are ready, move to the next topic to go over an example calculation.

To calculate the load on each sling segment we use the following equations:

TS1 = (Load x D2 x S1) / (H (D1 + D2)) , where TS1 is the Tension on sling 1 , D2 is the horizontal distance from the center of the pick point of the load to hoist 2, D1 is the horizontal distance from the center of the pick point of the load to hoist 1 and H is the vertical height from the load pick point to the lift anchor.

TS2 = (Load x D1 x S2) / (H (D1 + D2)) , where TS2 is the Tension on sling 2 , D1 is the horizontal distance from the center of the pick point of the load to hoist 1, D2 is the horizontal distance from the center of the pick point of the load to hoist 2 and H is the vertical height from the load pick point to the lift anchor.